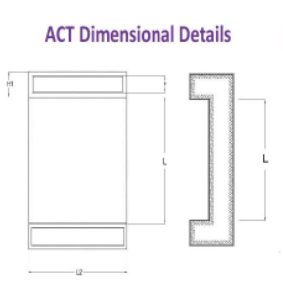

Model No. : ACT

Specification:

Rectangular Cross Talk Sound Attenuators made of high quality 0.8 mm thick Galvanized Sheet with 100mm thick baffles consisting of 48 Kg/m3 density rockwool. Different specifications can be made to customer requirements based of sound attenuation requirements. Designed in U shape as standard and can be made in Z shape as option.